Industrial Hard Chromium Plating

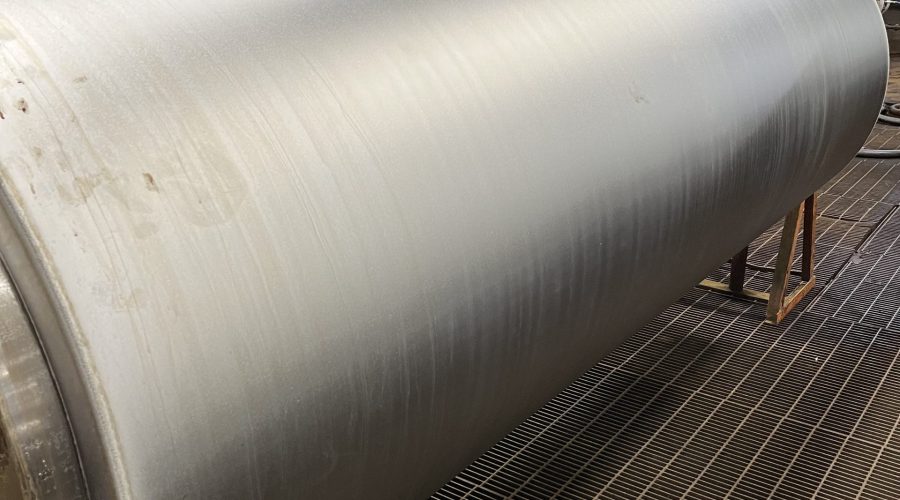

We bring a unique perspective to every industrial roll in our care.

In terms of plating, you can depend on detailed and expertly handled results.

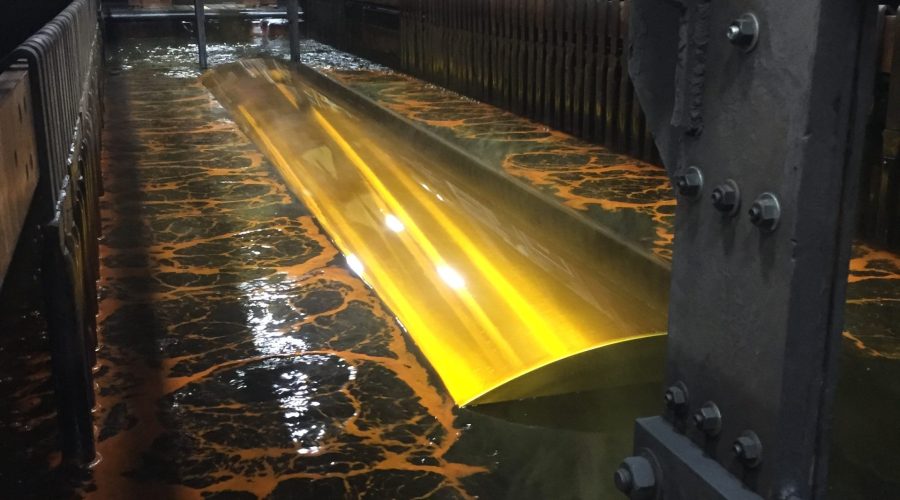

Among our many levels of expertise, chrome plating is among our primary in-house specialties that customers have come to depend upon. With precision and care, industrial rolls are immersed in plating tanks that can handle a range of sizes.

- 12’ diameter x 20’ length

- 7’ diameter x 38’ length

- 6’ diameter x 20’ length

- 4’ diameter x 30’ length

- 2’ diameter x 17’ length

- 2 ½’ diameter x 8’ length

Various weight capacities are also handled up to 60,000 lbs.

MP&P is one of the few facilities that can handle such a wide range of industrial roll sizes and perform all the critical specifications required for finishing, with the advantage of being all under one roof.

Process Assurance

The plating process is stringently maintained throughout the run. This has allowed us, for over 70 years, to ensure the proper amount of chromium being deposited. This process is absolutely vital to the surface finish that is required for each and every customer roll.

Plating Selection

Our team of experienced people can plate directly to:

- Stainless Steel

- Nickel

- Iron (of various grades)

- Carbon Steel

- Aluminum

…and other metal composites.

Engineered Custom Plating Fixtures

Our in-house engineers bring years of production experience to design custom plating fixtures that will accommodate parts with well-thought-out intricate designs. The custom fixtures we provide not only help to make the plating process easier but can prevent the industrial rolls from taking on any of the acid solution internally.

This is another method applied to assure the plating process runs smoothly and properly. Because there are many variables that come into play during electro-plating, our engineers and team members work closely together to deliver superior plating results.

See our Chrome Plating Tanks in Action