Attention to every detail.

For example, temperature control and stability is a key indicator of Heat Transfer Roll health. In today’s world of performance materials and adherence to international standards, uniform temperature control is essential.

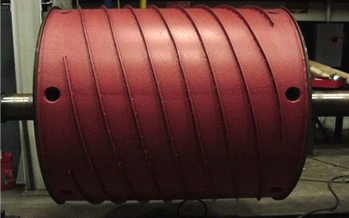

Whatever the industrial roll, we service it at MP&P

It directly impacts line speed as well as product quality and consistency. If you’ve identified an issue with your heat transfer rolls, the decision to refurbish or replace is best made by first determining the cause of performance decline.

Basic maintenance of your heat transfer roll, such as running treated water through your roll or acid-flushing with regularity, will help to maintain clean internal flow passages.

When scale build-up, excessive corrosion, and blockages inside the roll are significant, roll refurbish may be a more economical option than de-commissioning or discarding the roll. At Mirror Polishing & Plating, our goal is to provide you a means to salvage usable components when possible. Removing the outer shell and reconditioning the internal components can be solutions.

Engineers at MP&P are available to talk through your industrial roll challenges and help you evaluate whether repair or refurbish could save you time and money.

Call us today: 203.574.5400