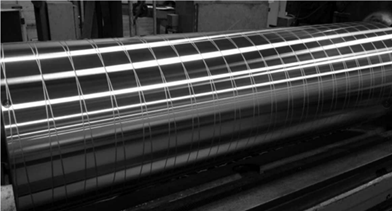

Industrial rolls at work, day after day face becoming worn and uneven as well as other forms of damage. Wear results decreased operations, loss or production and a host of issues. A worn roll running in a high-volume system will create any number of serious problems. Especially if it results in a change in the roll’s shape. It doesn’t take much to damage the surface and finish of a roll.

The Good News: Roll Life Extension!

Getting a worn roll back in productive operation is what we do and have been doing for over 60 years of continuous service. And in terms of roll solutions, we have solved hundreds and hundreds of roll problems. In some cases, the customer held no hope for the damaged roll’s recovery, but our talented people have brought those rolls extended production life. From inspection to final finish, MP&P’s technical staff watched carefully over every detail in every servicing stage of the roll.  Don’t let a damaged industrial roll concern you—let us give it new life.. Currently, MPP offers over 150 finishes to meet a variety of industrial needs and will work with you to determine the right finish for your application. Moreover, all categories of industrial rolls such as coating, calendar heat transfer, laminating and many more, are well understood by our in-house expert workers. Companies across the country send their rolls in need to MP&P at our facility in Connecticut. You should too!

Don’t let a damaged industrial roll concern you—let us give it new life.. Currently, MPP offers over 150 finishes to meet a variety of industrial needs and will work with you to determine the right finish for your application. Moreover, all categories of industrial rolls such as coating, calendar heat transfer, laminating and many more, are well understood by our in-house expert workers. Companies across the country send their rolls in need to MP&P at our facility in Connecticut. You should too!