Essential Factors:

- Temperature control and stability,

- These remain key factors of Heat Transfer Roll health.

- With growing performance materials and adherence to international standards, uniform temperature control is essential.

- Line speed is directly impacted.

- Product quality and consistency are affected.

When you detect an issue with your heat transfer rolls.

The key first step is to determine the cause of performance decline.

Basic maintenance: vital to your production:

Are you adhering to basic maintenance of your heat transfer roll?

The more economical solution:

When scale build-up, excessive corrosion, and blockages inside the roll are significant, roll refurbish may be a more economical option than de-commissioning or discarding the roll.

At Mirror Polishing & Plating, our goal is to provide you a means to salvage usable components when possible. Removing the outer shell and reconditioning the internal components can be solutions.

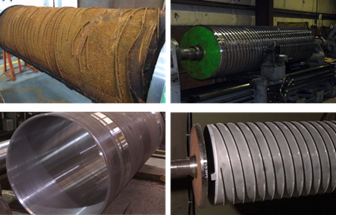

The refurbishing process—30% time savings!

Refurbishing a roll typically provides a 30% time savings versus a brand new roll.

- Remove the old outer shell

- Evaluate internal assembly to determine if the roll can be repaired

- Clean internal assembly and remove old spirals – replace with new spirals

- Apply corrosion resistant coating over entire internal assembly flow passages (optional)

- Turn and bore new outer shell for proper fit with reconditioned inner assembly

- Restore and recondition shaft (if required)

- Apply chrome plating or another coating system to complete refurbished heat transfer roll

We are here to help your facility stay productive when it comes to industrial roll performance. Call us today to learn more ways to save time, money and minimize downtime. 203-574-5400